Please contact Jisoo.Kwak for more information.

About

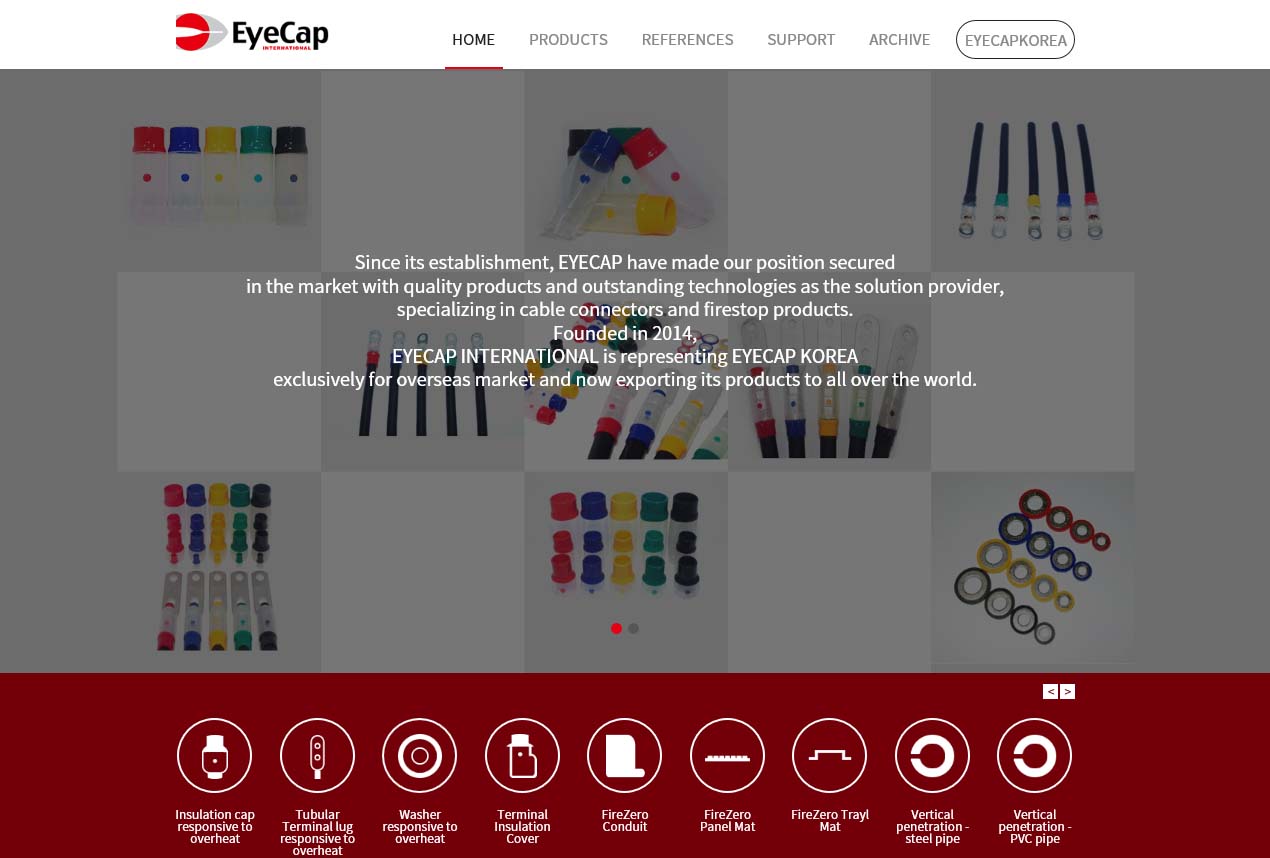

Eyecap is the innovator of cutting edge technology that cuts down on the labor, time, and costs involved in industrial oversight and damage prevention. We focus on fire prevention and tools that allow for easy inspection of temperature sensitive material. Our products will make industrial fire prevention easier for anyone that uses them.

Eyecap's vision for safer conditions in modern industries is accompanied by a reduction in the costs needed to create a safe environment. Our products make the old model of checking each sensitive electrical wire or equipment obsolete through innovative Eyecap technology. Every industry, no matter how simple, requires electricity and Eyecap's products will help you minimize the downsides to electricity. Eyecap will help you avert electrical fires, monitor heat generation of electrical wire terminals, and even confirm complete electrical wire connections.

Eyecap will continue to innovate new products that will decrease the risk of fire in industrial working conditions while also reducing the costs and labor of providing those conditions.

Why do we need EyeCap?

The problem with excessive heat generation occurs when the heat from the electrical connections starts to exceed 80 degees Celsius.

At that point, the PVC surrounding the electrical wires begins to degrade and creates gas. Furthermore, the heat buildup will create smoke at the connecting point between the electric wire and the lugs or terminals.

As the heat passes the ignition point, the electrical wire terminal will begin to create electric arcs which will eventually cause a fire. (Normal PVC electrical wires' ignition point is between 250~400 degees Celsius.)

Danger of Electric Arcs

The dangers of excessive heat generation at electric wire terminals.

Electrical arcs are caused when there is an electrical breakdown between the electrical wire connections and the current is discharged through a gas such as air.

These arcs can vary in length based on the strength of the current. Even if the strength of the current is low, the arc can exceed 1000 degees Celsius.

The arcs are therefore the primary reason for electrical fires in all industries.

How does it prevent fires?

The Cap allows you to prevent electrical fire and to confirm completion of electrical wire connections with nothing but a glance.

This cap is made of temperature sensitive material and its color will fade to white when the temperature reaches 60 degees Celsius. When the temperature drops below that point, the color will return.

Because of the ease of detection, workers, supervisors, inspectors, and others can quickly take necessary actions to respond in case of imminent danger.

Color coded caps help workers to classify electric wires without the need of labels.

Product Features

Our cap's design of a colored top and labeled transparent body allow you to see through the cover and still check the actual electrical wire connection.

The colored top will fade to white at 70 degees Celsius which allows you to check the status of the electrical wire connection with just one glance. When the temperature drops below that point, the color will return.

Our temperature sensitive electrical insulation caps have the electrical wire sizes printed on them so that you can easily identify them.

The cap is made from UL 94-V-0 and is therefore fire retardant. So, even if there is a fire, our covers will quickly prevent the fire from spreading.